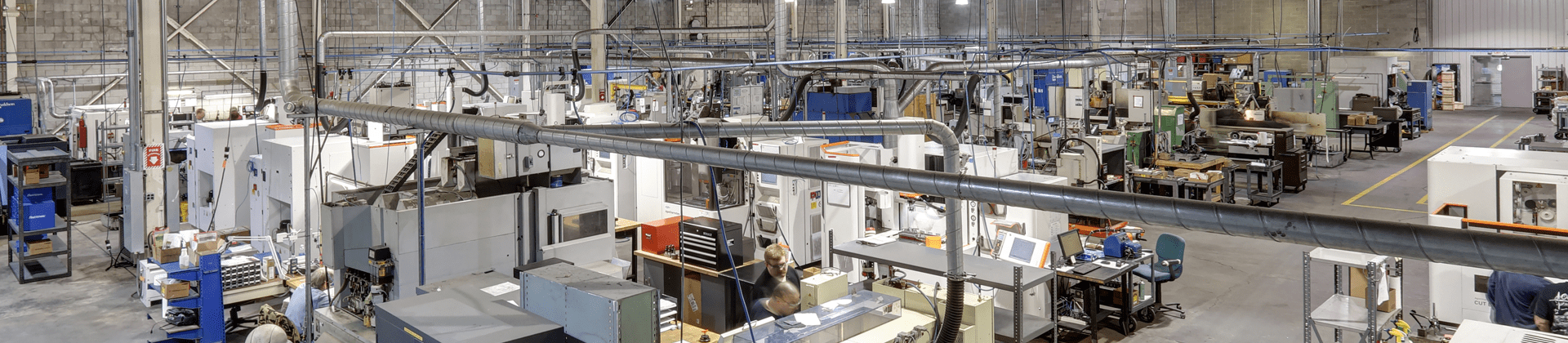

The Ability to Meet the Most Demanding Specifications

From six buildings totaling more than 30,000 square feet of production space, we manufacture our own tungsten carbide grades. By using our applications engineering expertise to control the quality of our tungsten carbide from powder to polish, including grinding, turning, prototyping and precision assembly, we meet the most demanding specifications. We maintain equally tight controls over the production of tooling made from tool steels.

NEED CONTENT ON GRINDING, TURNING, PROTOTYPING, PRECISION ASSEMBLY.

Sinter-HIP Advantages

Sinter-HIP is a method of thermal consolidation. The simultaneous application of heat and pressure consolidates the carbide during sintering, which results in a dense product that contains little or no porosity.

Hot Isostatic Pressing (HIP) Results in Superior Reliability

- Automotive

- Aerospace

- General Industrial

- Heavy Equipment

- Oil & Gas

Beyond excellent transverse rupture strength, sinter-HIPed carbide preforms offer outstanding:

- Compressive Strength (> 600,000 psi)

- Torsional Strength

- Resistance to Deflection, Corrosion & Wear

- Fracture Toughness

CAPABILITIES

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

© 2019 General Carbide Corp | All rights reserved

Terms & Conditions | Privacy Policy

Greensburg, PA 15601