The Ability to Meet the Most Demanding Specifications

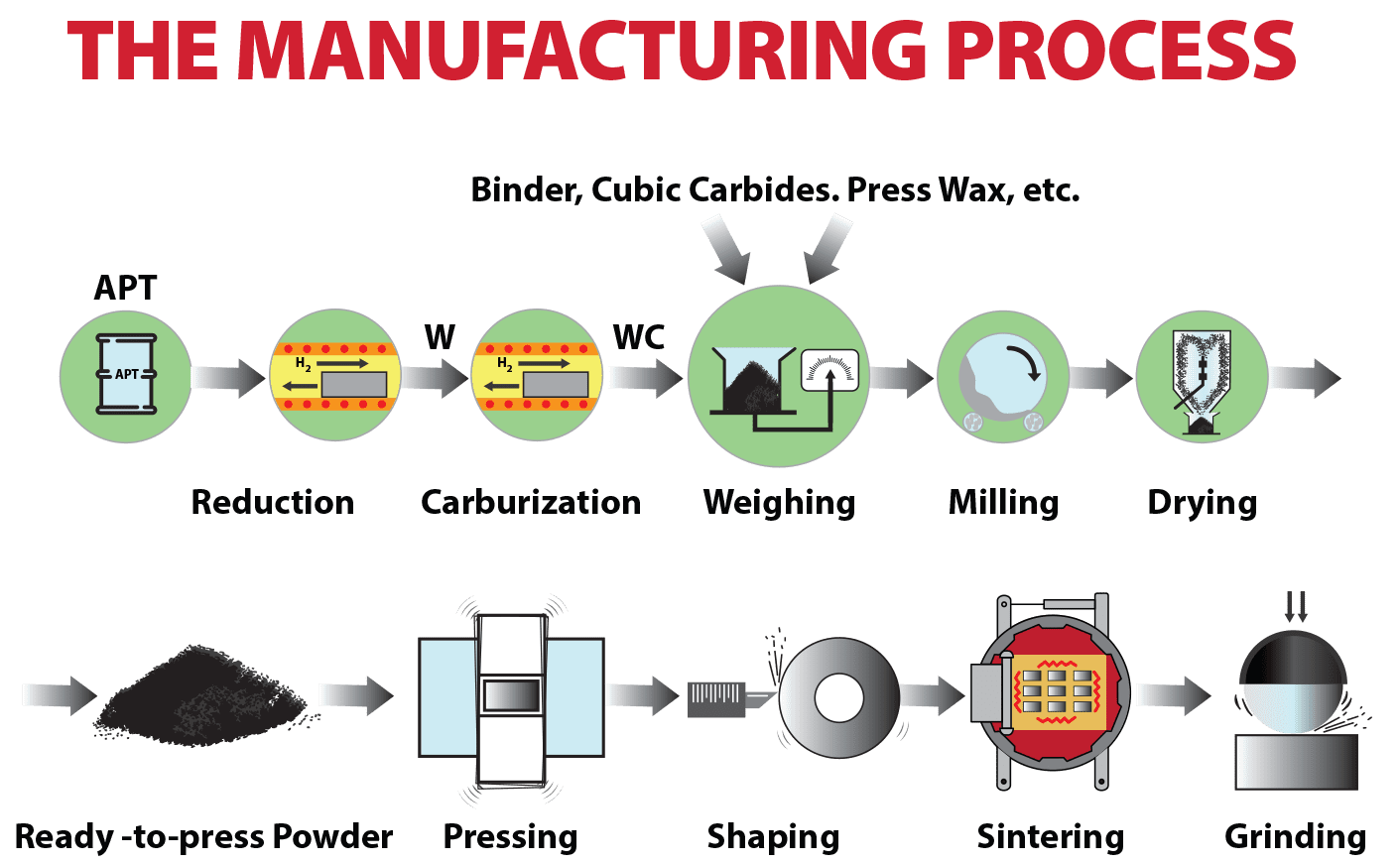

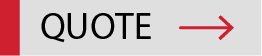

From four buildings in Greensburg, PA (near Pittsburgh), totaling more than 100,000 square feet of production space, we manufacture our own tungsten carbide grades. By using our applications engineering expertise to control the quality of our tungsten carbide from powder to polish, including grinding, machining, finishing, polishing and assembly, we meet the most demanding specifications.

At General Carbide, we’re more than just a carbide company. That’s because we manufacture a complete line of steel tooling. That addition to our capabilities has solidified our position as a leading manufacturer of high precision tool & die components.

By offering a wide range of steel grades, we can help you meet application requirements for longer runs.

Whether your tooling is made from carbide or steel, we maintain tight controls over production to give you the outstanding quality, delivery and customer service that have made us an industry leader for more than 50 years.

General Carbide’s Vertical Integration